Capacity: 24′ log length by 36″ diameter log cut capacity

Engine: 51 HP CAT® Diesel Engine

Weight: 7000 lbs.

Model LM 4 Portable Sawmill

If you can find a heavier, more powerful portable Sawmill mill with more standard equipment than the LOG-MASTER Model LM 4 Portable Sawmill CAT® powered sawmill, then you should buy that sawmill! You want power and performance…you want it at a low price…you want the Model LM 4 Portable Sawmill from LOG-MASTER! Powered by the 51 HP CAT®, 4 cylinder, liquid cooled diesel engine. LOG-MASTER is the first portable sawmill to use these CAT® diesel engines. The CAT® powered engines set the world’s standard on high performance, rugged, reliable and dependable high-torque diesel power. This portable sawmill will effortlessly cut a hefty 36″ diameter log 24′ long.

Click here to view or download a PDF brochure of this model.

Standard Features Include:

- 51 HP CAT® Diesel Engine with 105 FT/LB of Torque. Caterpillar has a world wide service network that you can rely on.

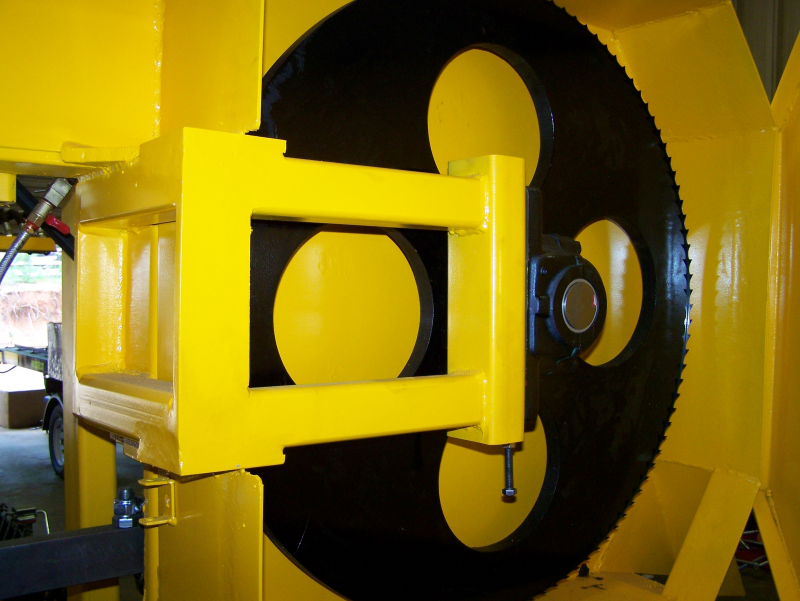

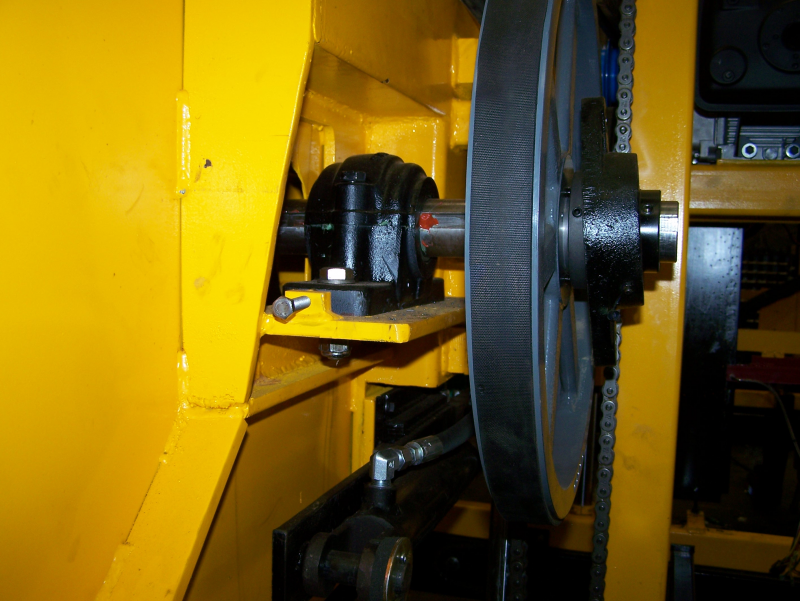

- 30″ solid steel dynamically balanced machined band wheels (not cast iron pulleys!)

- Weighs approximately 7500 lbs.

- 24′ log length (additional length available) by 36″ diameter log cut capacity.

- Hydraulic set works system with 14 presets…the most in the industry.

- Board drag back system is made out of ½” thick steel.

- Clean side cut system.

- 1-1/2″ wide by 19’1″ blade length.

- Bevel siding maker attachment is standard.

- 8 Quick level jack stations.

- Stationary operator station (no need to walk around to operate your sawmill, all of the functions are in one place so you can take control of your sawmilling operation).

- 6 post head frame made out of 3” x 2” x ¼” rectangular tubing.

- The heaviest twin beam frame built today. Made out of 6” x 3” x ¼” thick rectangular tubing.

- No side load main shaft. The main shaft has a bearing in the front and the back of the drive side band wheel. The drive shaft is 2” thick 1144 TGP Stress proof shafting material.

- The built in drip system lubricates both sides of the band saw blade.

All Hydraulic Functions Are:

- Heavy duty 6 post hydraulic head rig. Made from 3” x 2” x ¼” wall thick steel.

- Hydraulic forward and reverse of the head rig is adjustable from the operator station. The more you push the handle the faster you saw!

- Hydraulic up/down of the head rig with the movement of the lever. No push buttons, toggle switched or electric cords to cut here just push the handle and the head move up or down!

- Hydraulic guide arm in and out push the lever and the guide are (moved by a hydraulic cylinder) move in and out.

- 2 hydraulic rolling toe board moves up and down on a 3” hydraulic cylinder. You have the power to level the biggest of logs.

- Hydraulic log loader is made from 3” x 2” x ¼” thick steel tubing to load the biggest of logs. The log loader has a 3” x 12” stroke hydraulic cylinder on each log loading arm. There are three log loading arms on the sawmill.

- Hydraulic front dog is made from solid 1” x 2” (1018 cold finished steel) that has been heat treated to last a lifetime. The hydraulic front dog moves up and down on a hydraulic cylinder.

- The Hydraulic clamp (2” x 24” hydraulic cylinder) has the power to push the biggest of log and to clamp them tight. No motor here, motors do not have the clamping force that a cylinder does.

- Hydraulic back dogs move up and down in a vertical motion. Made out of 1” x 2” heat treated steel and moving up and down on there own 2” x 12” hydraulic cylinder these hydraulic back dogs don’t bend over time like the horizontal dog.

- Hydraulic chain log turner uses a planetary drive motor (like the wheel motors on dozers or skid steer loaders for the drive wheels) to turn the chain on the chain turner. You have not seen a chain turner work until you have seen the Log-Master chain turner work!

Options for the LM 4 Portable Sawmill are:

- Unlimited Computer setworks.

- Hydraulic Debarker